- August 16, 2024

- by Jesse Feinberg

It’s no surprise that installing solar is good for the environment: solar energy produces zero emissions. Nor is it a surprise that businesses installing solar can realize an attractive ROI (especially for larger systems achieving economies of scale). But for many businesses in someone else’s supply chain, solar is now emerging as a must-have to remain competitive in the procurement process.

In this post, we’re zooming in on the auto industry, where automakers have set increasingly aggressive emissions reductions targets. These targets include emissions reductions in their supply chains. To effect these reductions, automakers now commonly require their parts suppliers to reduce their own emissions – or at least have a plan in place to do so.

What this means, in short, is that auto parts suppliers – and, increasingly, these suppliers’ suppliers – need solutions like onsite solar in order to remain competitive. We’ll explore more about why this is happening and how the auto parts industry can harness solar to their advantage.

Automaker sustainability goals include their supply chains

Every major U.S. automaker and many international automakers have set sustainability goals that include significant supply chain emissions reductions. This is because they have set their sustainability goals through the Science Based Targets Initiative (SBTi), and one of the requirements of SBTi is that “…if a company’s scope 3 emissions are 40% or more of total scope 1, 2, and 3 emissions (i.e. the vast majority of companies), a scope 3 target is required.”

Supplier emissions are categorized under Scope 3 – and for most automakers, their scope 3 emissions (indirect emissions, which include both upstream supply chain and downstream customer emissions) easily exceed this ‘40% of overall emissions’ threshold.

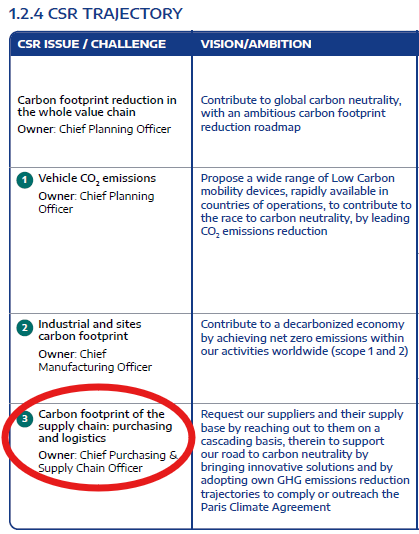

This means that all major automakers are required to set Scope 3 emissions reductions targets and, as a result, are now applying pressure to their suppliers to achieve them. For example, here’s the high level description of the Stellantis Climate Change goals in its 2023 Corporate Social Responsibility (CSR) report:

Source: Stellantis CSR Report 2023

In goal number 3 (circled in red), Stellantis tasks its Chief Purchasing & Supply Chain Officer with (in the second column of the image) working with suppliers to reduce the suppliers’ carbon emissions footprint.

Ford and GM have also both set Scope 3 targets, in each case a 50% emissions reduction by 2050. In fact, according to SP Global, nearly all major US. and non-U.S. automakers have also set meaningful scope 3 emission reduction targets, including internationally BMW, Jaguar, Nissan, Renault, Toyota, Volkswagen, and Volvo.

Auto parts suppliers can gain a competitive edge by cutting emissions

Automaker sustainability goals are obviously a positive step in terms of climate change, but they also have significant commercial implications. Stellantis, Ford, GM, and others are making procurement decisions on the basis of which suppliers have set emissions targets and which are making the most progress towards achieving them.

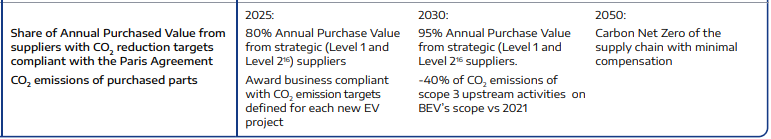

Stellantis will require that by 2025, at least 80% of annual purchase value from its Level 1 and 2 suppliers comes from those suppliers which have set emissions reduction targets compliant with the Paris Agreement. By 2030, this escalates to 95% and by 2050, 100% (see image below). In other words, reducing emissions will make suppliers much more competitive in Stellantis procurements.

Source: Stellantis CSR Report 2023

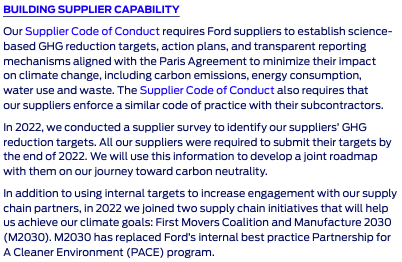

Ford is taking similar actions. Ford’s “Supplier Code of Conduct” (see image below) requires Ford suppliers to set science-based emissions reductions targets and create action plans to achieve them:

Source: Ford Climate Change Report 2023

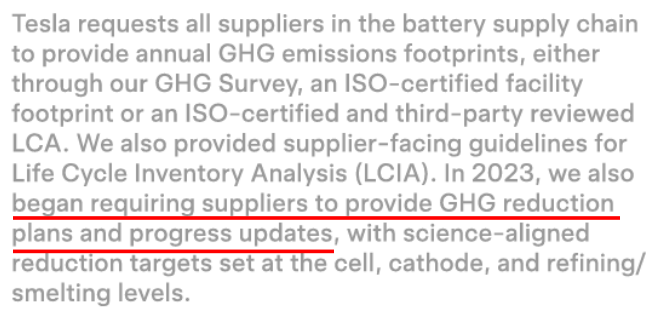

GM is evaluating supplier decarbonization efforts through its “Supplier Sustainability Goals Framework” and directly measuring year-over-year supplier energy use at 680 supplier sites through its Manufacture 2030 initiative. Tesla requires many suppliers “to provide GHG reduction plans and progress updates” (see image below).

Source: Tesla Impact Report 2023

There are many other examples. The short version is that remaining competitive in the auto supply market likely means thinking about emissions reductions. Some automakers are already incorporating supply chain sustainability into their procurement decision-making framework – and those that haven’t yet won’t be far behind.

Renewable energy is an attractive way to cut emissions and save money

If you’re an auto parts supplier and you want to reduce emissions to improve your competitiveness, you may be wondering where to start.

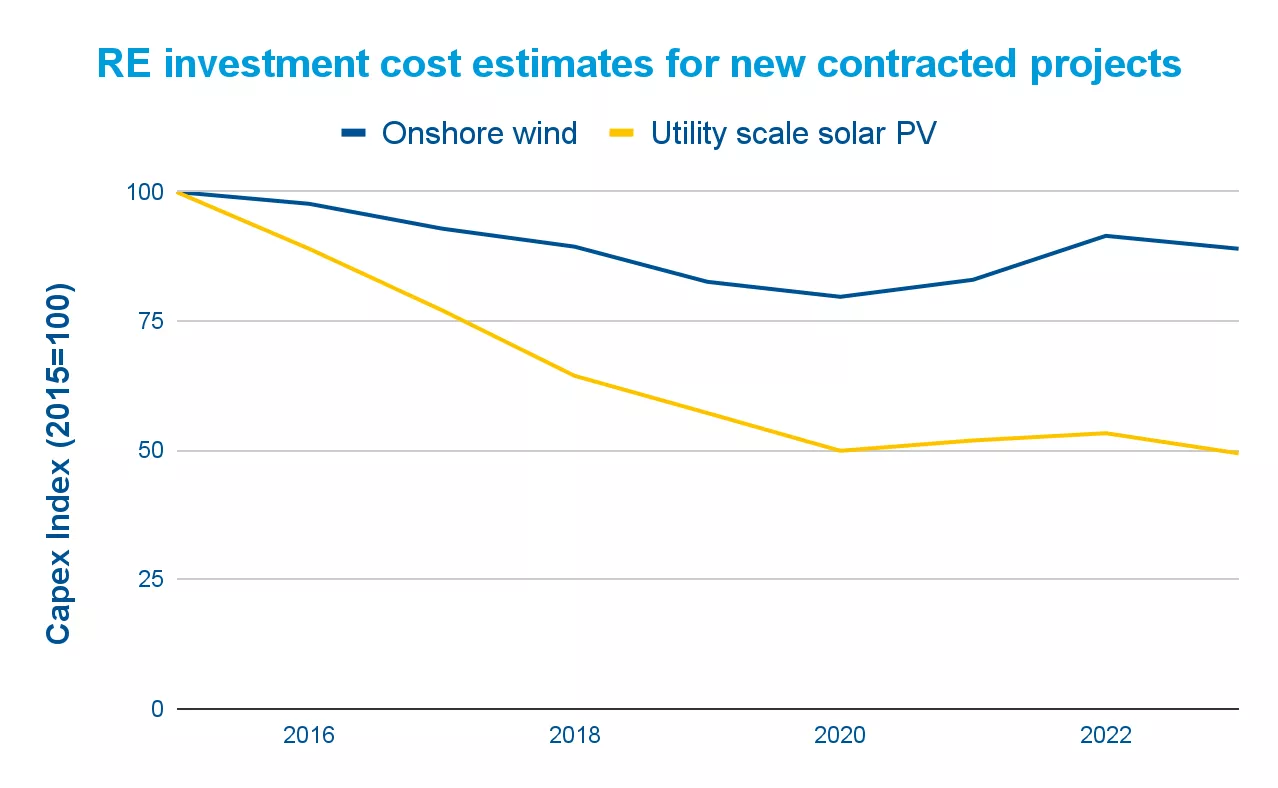

Under the greenhouse gas accounting framework, emissions can be divided into three categories: scope 1 (direct emissions), scope 2 (emissions from purchased electricity), and scope 3 (indirect emissions upstream and downstream in the value chain). Typically, the best place to start is with scope 2 – emissions from purchased electricity. This is because decarbonizing electricity doesn’t just reduce emissions; it also (if done right) can provide a significant ROI relative to fossil fuel electricity. This is because renewable energy, especially solar, has plummeted in cost in the last decade, with solar now costing less than 50% of what it did in 2015 (see graph below).

Source: U.S. National Renewable Energy Laboratory (NREL)

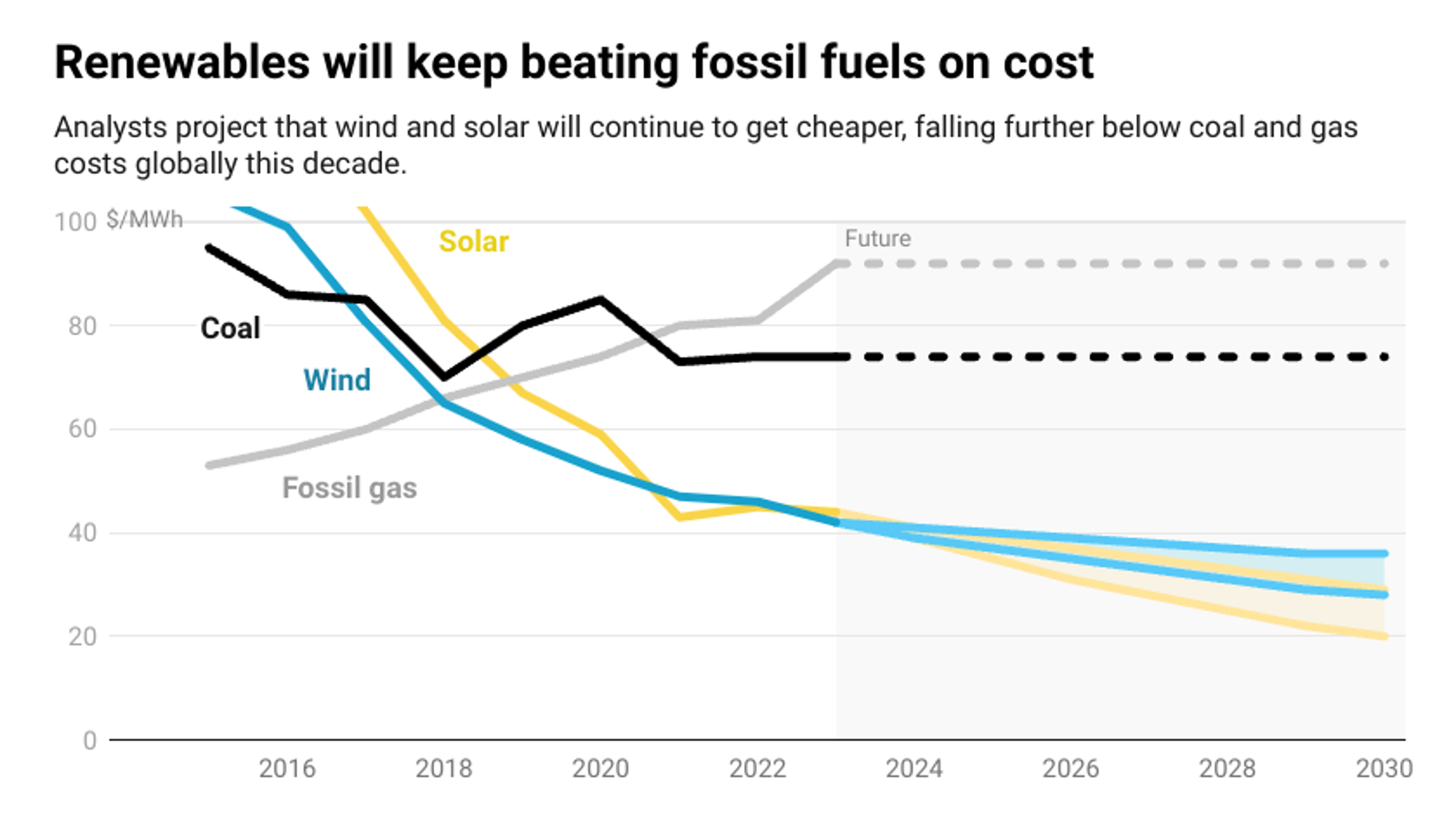

In fact, electricity generated by wind and solar now rates as cheaper than electricity produced by fossil fuels. This has been true since about 2018 and the trend is only accelerating (see graph below).

Source: CleanTechnica

By sourcing renewable electricity rather than fossil fuel electricity, an organization can save money relative to business-as-usual.

Onsite solar is really well-suited to auto parts supplier needs

For large, energy-intensive manufacturing operations, like auto parts suppliers, onsite solar can provide a strong ROI while delivering the scope 2 emissions reductions needed to remain competitive in procurements. However, the return on investment varies widely depending on the facility.

A good rule of thumb is that onsite solar provides a strong ROI when:

- Your electricity supplier’s charges per kilowatt-hour are high,

- Your electricity consumption is high enough to allow a large onsite project with economies of scale, and

- There’s available land onsite or on an adjacent property.

If any of these aren’t true, then alternative solutions like an off-site solar system or simply buying unbundled RECs might make more sense for reducing emissions. But if your facility happens to check all three boxes, then onsite solar is likely to achieve your emissions reduction goal and deliver the most attractive return on investment.

Learn More

Does it seem like onsite solar might be a good solution to meet your economic and energy goals? Fill out the form below to get started.

Nokomis Energy is a clean energy developer focused on the Upper Midwest and Mountain West regions. Our mission is to identify opportunities to create clean, low-cost energy projects for our customers. We work directly with our customers and partners to implement and build clean energy solutions that work for your specific needs.